In construction, selecting the right materials is crucial for the success and longevity of a project. One such material that has become integral in the industry is the Concrete Masonry Unit (CMU). This comprehensive guide will explore what CMU is, its types, applications, benefits, challenges, and more, providing you with a thorough understanding of this essential construction material.

Definition of CMU

What Does CMU Stand For?

CMU stands for Concrete Masonry Unit, a standardized rectangular block used in building construction. CMUs are made from a mixture of cement, water, and aggregates such as sand, gravel, or crushed stone.

Historical Background

The use of CMUs dates back to the early 20th century when they quickly gained popularity due to their durability and versatility. Over the years, CMUs have evolved to meet the changing needs of the construction industry, becoming a preferred choice for many builders.

Types of CMU

Standard CMU

Description

Standard CMUs are the most common type, typically measuring 8x8x16 inches. They come in various sizes and shapes to suit different construction needs.

Uses

Standard CMUs are widely used in foundations, walls, and partitions due to their strength and cost-effectiveness.

Architectural CMU

Features

Architectural CMUs are designed with aesthetic appeal in mind. They come in various textures, colors, and finishes to enhance the visual appeal of a building.

Applications

Architectural CMUs are commonly used in decorative facades and feature walls, where both appearance and functionality are important.

Specialty CMU

Insulated CMU

Insulated CMUs have built-in insulation properties, making them ideal for energy-efficient buildings.

Soundproof CMU

Soundproof CMUs are designed to reduce noise transmission, making them suitable for buildings in noisy environments.

Fire-Rated CMU

Fire-rated CMUs offer enhanced fire resistance, providing added safety in fire-prone areas.

Manufacturing Process of CMU

Raw Materials

CMUs are made from a mixture of cement, water, and aggregates such as sand, gravel, or crushed stone. The choice of aggregates can affect the properties of the final product.

Production Process

The manufacturing process involves mixing the raw materials, pouring the mixture into molds, and compacting it. After molding, the blocks are cured to ensure they reach the required strength. Curing methods can include steam curing or autoclaving, depending on the desired properties of the CMUs.

Quality Control Measures

Quality control is essential in CMU manufacturing to ensure consistency and reliability. This includes testing the blocks for strength, density, and other properties.

Environmental Considerations

The production of CMUs can have environmental impacts, but manufacturers are increasingly adopting sustainable practices, such as using recycled materials and reducing energy consumption during production.

Applications of CMU in Construction

Residential Construction

Uses

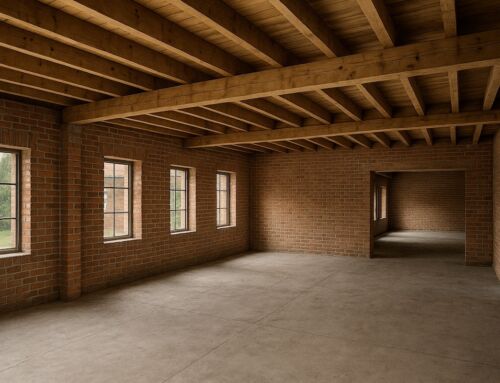

In residential construction, CMUs are commonly used for foundations, walls, and basements. They provide a strong and durable structure that can withstand various environmental conditions.

Commercial Construction

Uses

CMUs are widely used in commercial buildings such as office buildings, schools, and hospitals. Their strength, fire resistance, and versatility make them suitable for various applications.

Industrial Construction

Uses

In industrial construction, CMUs are used in warehouses, factories, and storage facilities. They offer durability and resistance to harsh industrial environments.

Landscape and Outdoor Structures

Uses

CMUs are also used in landscaping and outdoor structures such as retaining walls, fences, and garden structures. They provide a sturdy and attractive solution for various outdoor applications.

Advantages of Using CMU

Durability and Strength

CMUs are known for their durability and strength, making them a reliable choice for various construction projects.

Fire Resistance

CMUs have a high fire-resistance rating, providing added safety in fire-prone areas.

Thermal Insulation

CMUs provide good thermal mass, helping to regulate indoor temperatures and improve energy efficiency.

Sound Insulation

CMUs reduce noise levels, making them suitable for buildings in noisy environments.

Versatility

CMUs are versatile and can be used in various applications, from residential to industrial construction.

Cost-Effectiveness

CMUs are affordable and widely available, making them a cost-effective choice for many builders.

Low Maintenance

CMUs require minimal maintenance, making them a practical choice for long-term use.

Challenges and Considerations

Weight

CMUs are heavy and require careful handling during transportation and installation.

Moisture Issues

Proper waterproofing is essential to prevent moisture penetration and related issues such as mold and mildew.

Structural Limitations

While CMUs are strong, they may not be suitable for all structural designs. Consulting with an engineer is recommended for complex projects.

Aesthetic Limitations

While architectural CMUs offer various design options, some may find the aesthetic appeal of CMUs limited compared to other materials.

Environmental Impact

The production of CMUs can be resource-intensive. However, many manufacturers are adopting sustainable practices to mitigate environmental impacts.

Installation and Construction Techniques

Site Preparation and Foundation Work

Proper site preparation and foundation work are crucial for the successful installation of CMUs. Ensure the foundation is stable and level.

Laying CMU Blocks

Tools and Materials

You will need trowels, levels, mortar, and other tools to lay CMU blocks.

Techniques

Align and level each block carefully to ensure a sturdy and straight wall.

Mortar Application

Types of Mortar

Common types of mortar include Type N, S, and M, each with different properties.

Mixing and Application

Consistency is key for mortar strength. Follow the manufacturer’s instructions for mixing and applying mortar.

Reinforcement and Grouting

Reinforcement

Use rebar and wire mesh to reinforce CMU walls for added strength.

Grouting

Fill cavities with grout to enhance the structural integrity of CMU walls.

Finishing Touches

Surface Treatments

Apply paint, stucco, or sealants to protect and enhance the appearance of CMU surfaces.

CMU vs Concrete Wall

A CMU (Concrete Masonry Unit) wall and a concrete wall differ in both structure and application. CMU walls are constructed using individual concrete blocks, often with hollow cores, which are stacked and reinforced with steel and mortar.

They offer flexibility in design and are commonly used in commercial buildings and residential projects for both interior and exterior walls. In contrast, a concrete wall is typically a solid, monolithic structure made from poured concrete. It is known for its higher strength, durability, and resistance to weather and fire, making it ideal for foundations, retaining walls, and heavy-duty applications.

Both options offer strong, long-lasting solutions, but CMU walls may provide more versatility in design, while concrete walls excel in structural strength.

Related Reading – What is Tuckpointing in Masonry?

FAQs About CMU in Construction

What is the difference between CMU and concrete block?

CMU is a specific type of concrete block known for its standardized size and shape, while concrete blocks can vary in dimensions and compositions.

What are CMU walls used for?

CMU walls are used in load-bearing applications, fire-rated walls, and partitions due to their strength and durability.

Is CMU the same as a brick?

No, CMU and brick differ in material composition, size, and structural properties. CMUs are larger and offer different thermal and acoustic properties compared to bricks.

How long does a CMU structure last?

With proper maintenance, CMU structures can last for decades, often outlasting many other construction materials.

Can CMU be used in seismic zones?

Yes, with appropriate reinforcement, CMU can be used in seismic zones.

What are the maintenance requirements for CMU structures?

CMU structures require minimal maintenance, primarily focusing on addressing any cracks or moisture issues.

How does CMU compare to other building materials like bricks or wood?

CMU offers superior strength, fire resistance, and durability compared to wood and many types of bricks.

Conclusion

At Dixon Inc., we understand the vital role that Concrete Masonry Units (CMUs) play in modern construction. Their strength, versatility, and cost-effectiveness make them an invaluable material for a wide range of projects. Whether you are working on a residential, commercial, industrial, or landscape project, CMUs provide a reliable and durable solution.

As a Minority Business Enterprise, we are proud to offer a comprehensive range of services, including masonry services, historic restoration, design assistance, project management, and general construction services throughout the Midwest. Our commitment to excellence and attention to detail ensure that every project we undertake is completed to the highest standards.

We invite you to explore the quality and reliability of our CMU products and services. Trust Dixon Inc. to help you achieve your construction goals with the best materials and expertise available. Contact us today for all your masonry and construction needs.